Baking is a process of cooking by dry heat, especially in some kind of oven. It is probably the oldest cooking method. Bakery products, which include bread, rolls, cookies, pies, pastries, and muffins, are usually prepared from flour or meal derived from some form of grain. Bread, already a common staple in prehistoric times, provides many nutrients in the human diet.

History

The earliest processing of cereal grains probably involved parching or dry roasting of collected grain seeds. Flavour, texture, and digestibility were later improved by cooking whole or broken grains with water, forming gruel or porridge. It was a short step to the baking of a layer of viscous gruel on a hot stone, producing primitive flat bread. More sophisticated versions of flat bread include the Mexican tortilla, made of processed corn, and the chapati of India, usually made of wheat.

Baking techniques improved with the development of an enclosed baking utensil and then of ovens, making possible thicker baked cakes or loaves. The phenomenon of fermentation, with the resultant lightening of the loaf structure and development of appealing flavours, was probably first observed when doughs or gruels, held for several hours before baking, exhibited spoilage caused by yeasts. Some of the effects of the microbiologically induced changes were regarded as desirable, and a gradual acquisition of control over the process led to traditional methods for making leavened bread loaves. Early baked products were made of mixed seeds with a predominance of barley, but wheat flour, because of its superior response to fermentation, eventually became the preferred cereal among the various cultural groups sufficiently advanced in culinary techniques to make leavened bread.

Brewing and baking were closely connected in early civilizations. Fermentation of a thick gruel resulted in a dough suitable for baking; a thinner mash produced a kind of beer. Both techniques required knowledge of the “mysteries” of fermentation and a supply of grain. Increasing knowledge and experience taught the artisans in the baking and brewing trades that barley was best suited to brewing, while wheat was best for baking.

By 2600 BC the Egyptians, credited with the first intentional use of leavening, were making bread by methods similar in principle to those of today. They maintained stocks of sour dough, a crude culture of desirable fermentation organisms, and used portions of this material to inoculate fresh doughs. With doughs made by mixing flour, water, salt, and leaven, the Egyptian baking industry eventually developed more than 50 varieties of bread, varying the shape and using such flavouring materials as poppyseed, sesame, and camphor. Samples found in tombs are flatter and coarser than modern bread.

The Egyptians developed the first ovens. The earliest known examples are cylindrical vessels made of baked Nile clay, tapered at the top to give a cone shape and divided inside by a horizontal shelflike partition. The lower section is the firebox, the upper section is the baking chamber. The pieces of dough were placed in the baking chamber through a hole provided in the top.

In the first two or three centuries after the founding of Rome, baking remained a domestic skill with few changes in equipment or processing methods. According to Pliny the Elder, there were no bakers in Rome until the middle of the 2nd century BC. As well-to-do families increased, women wishing to avoid frequent and tedious bread making began to patronize professional bakers, usually freed slaves. Loaves molded by hand into a spheroidal shape, generally weighing about a pound, were baked in a beehive-shaped oven fired by wood. Panis artopticius was a variety cooked on a spit, panis testuatis in an earthen vessel.

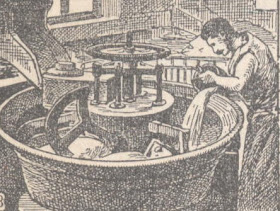

Although Roman professional bakers introduced technological improvements, many were of minor importance, and some were essentially reintroductions of earlier developments. The first mechanical dough mixer, attributed to Marcus Virgilius Euryasaces, a freed slave of Greek origin, consisted of a large stone basin in which wooden paddles, powered by a horse or donkey walking in circles, kneaded the dough mixture of flour, leaven, and water.

Guilds formed by the miller-bakers of Rome became institutionalized. During the 2nd century AD, under the Flavians, they were organized into a “college” with work rules and regulations prescribed by government officials. The trade eventually became obligatory and hereditary, and the baker became a kind of civil servant with limited freedom of action.

During the early Middle Ages, baking technology advances of preceding centuries disappeared, and bakers reverted to mechanical devices used by the ancient Egyptians and to more backward practices. But in the later Middle Ages the institution of guilds was revived and expanded. Several years of apprenticeship were necessary before an applicant was admitted to the guild; often an intermediate status as journeyman intervened between apprenticeship and full membership (master). The rise of the bakers' guilds reflected significant advances in technique. A 13th-century French writer named 20 varieties of bread varying in shape, flavourings, preparation method, and quality of the meal used. Guild regulations strictly governed size and quality. But outside the cities bread was usually baked in the home. In medieval England rye was the main ingredient of bread consumed by the poor; it was frequently diluted with meal made from other cereals or leguminous seeds. Not until about 1865 did the cost of white bread in England drop below brown bread.

At that time improvements in baking technology began to accelerate rapidly, owing to the higher level of technology generally. Ingredients of greater purity and improved functional qualities were developed, along with equipment reducing the need for individual skill and eliminating hand manipulation of bread doughs. Automation of mixing, transferring, shaping, fermentation, and baking processes began to replace batch processing with continuous operations. The enrichment of bread and other bakery foods with vitamins and minerals was a major accomplishment of the mid-20th-century baking industry.

Ingredients

Flour, water, and leavening agents are the ingredients primarily responsible for the characteristic appearance, texture, and flavour of most bakery products. Eggs, milk, salt, shortening, and sugar are effective in modifying these qualities, and various minor ingredients may also be used.

Flour

Wheat flour is unique among cereal flours in that, when mixed with water in the correct proportions, its protein component forms an elastic network capable of holding gas and developing a firm spongy structure when baked. The proteinaceous substances contributing these properties are known collectively as gluten. The suitability of a flour for a given purpose is determined by the type and amount of its gluten content. These characteristics are controlled by the genetic constitution and growing conditions of the wheat from which the flour was milled, as well as the milling treatment applied.

Low-protein, soft-wheat flour is appropriate for cakes, pie crusts, cookies (sweet biscuits), and other products not requiring great expansion and elastic structure. High-protein, hard-wheat flour is adapted to bread, hard rolls, soda crackers, and Danish pastry, all requiring elastic dough and often expanded to low densities by the leavening action.

Leavening agents

Pie doughs and similar products are usually unleavened, but most bakery products are leavened, or aerated, by gas bubbles developed naturally or folded in. Leavening may result from yeast or bacterial fermentation, from chemical reactions, or from the distribution in the batter of atmospheric or injected gases.

Yeast

All commercial breads, except salt-rising types and some rye bread, are leavened with bakers' yeast, composed of living cells of the yeast strain Saccharomyces cerevisiae. A typical yeast addition level might be 2 percent of the dough weight. Bakeries receive yeast in the form of compressed cakes containing about 70 percent water or as dry granules containing about 8 percent water. Dry yeast, more resistant to storage deterioration than compressed yeast, requires rehydration before it is added to the other ingredients. “Cream” yeast, a commercial variety of bakers' yeast made into a fluid by the addition of extra water, is more convenient to dispense and mix than compressed yeast, but it also has a shorter storage life and requires additional equipment for handling.

Bakers' yeast performs its leavening function by fermenting such sugars as glucose, fructose, maltose, and sucrose. It cannot use lactose, the predominant sugar of milk, or certain other carbohydrates. The principal products of fermentation are carbon dioxide, the leavening agent, and ethanol, an important component of the aroma of freshly baked bread. Other yeast activity products also flavour the baked product and change the dough's physical properties.

The rate at which gas is evolved by yeast during the various stages of dough preparation is important to the success of bread manufacture. Gas production is partially governed by the rate at which fermentable carbohydrates become available to the yeast. The sugars naturally present in the flour and the initial stock of added sugar are rapidly exhausted. A relatively quiescent period follows, during which the yeast cells become adapted to the use of maltose, a sugar constantly being produced in the dough by the action of diastatic enzymes on starch. The rate of yeast activity is also governed by temperature and osmotic pressure, the latter primarily a function of the water content and salt concentration.

Baking soda

Layer cakes, cookies (sweet biscuits), biscuits, and many other bakery products are leavened by carbon dioxide from added sodium bicarbonate (baking soda). Added without offsetting amounts of an acidic substance, sodium bicarbonate tends to make dough alkaline, causing flavour deterioration and discoloration and slowing carbon dioxide release. Addition of an acid-reacting substance promotes vigorous gas evolution and maintains dough acidity within a favourable range.

Carbon dioxide produced from sodium bicarbonate is initially in dissolved or combined form. The rate of gas release affects the size of the bubbles produced in the dough, consequently influencing the grain, volume, and texture of the finished product. Much research has been devoted to the development of leavening acids capable of maintaining the rate of gas release within the desired range. Acids such as acetic, from vinegar, or lactic, from sour milk, usually act too quickly; satisfactory compounds include cream of tartar (potassium acid tartrate), sodium aluminum sulfate (alum), sodium acid pyrophosphate, and various forms of calcium phosphate.

Baking powder

Instead of adding soda and leavening acids separately, most commercial bakeries and domestic bakers use baking powder, a mixture of soda and acids in appropriate amounts and with such added diluents as starch, simplifying measuring and improving stability. The end products of baking-powder reaction are carbon dioxide and some blandly flavoured harmless salts. All baking powders meeting basic standards have virtually identical amounts of available carbon dioxide, differing only in reaction time. Most commercial baking powders are of the double-acting type, giving off a small amount of available carbon dioxide during the mixing and makeup stages, then remaining relatively inert until baking raises the batter temperature. This type of action eliminates excessive loss of leavening gas, which may occur in batter left in an unbaked condition for long periods.

Entrapped air and vapour

Angel food cakes, sponge cakes, and similar products are customarily prepared without either yeast or chemical leaveners. Instead, they are leavened by air entrapped in the product through vigorous beating. This method requires a readily foaming ingredient capable of retaining the air bubbles, such as egg whites. To produce a cake of fine and uniform internal structure, the pockets of air folded in during beating are rapidly subdivided into small bubbles with such mixing utensils as wire whips, or whisks.

The vaporization of volatile fluids (e.g., ethanol) under the influence of oven heat can have a leavening effect. Water-vapour pressure, too low to be significant at normal temperatures, exerts substantial pressure on the interior walls of bubbles already formed by other means as the interior of the loaf or cake approaches the boiling point. The expansion of such puff pastry as used for napoleons (rich desserts of puff pastry layers and whipped cream or custard) and vol-au-vents (puff pastry shells filled with meat, fowl, fish, or other mixtures) is entirely due to water-vapour pressure.

Shortening

Fats and oils are essential ingredients in nearly all bakery products. Shortenings have a tenderizing effect in the finished product and often aid in the manipulation of doughs. In addition to modifying the mouth feel or texture, they often add flavour of their own and tend to round off harsh notes in some of the spice flavours.

The common fats used in bakery products are lard, beef fats, and hydrogenated vegetable oils. Butter is used in some premium and specialty products as a texturizer and to add flavour, but its high cost precludes extensive use. Cottonseed oil and soybean oil are the most common processed vegetable oils used. Corn, peanut, and coconut oils are used to a limited extent; fats occurring in other ingredients, such as egg yolks, chocolate, and nut butters, can have a shortening effect if the ingredients are present in sufficient quantity.

Breads and rolls often contain only 1 or 2 percent shortening; cakes will have 10 to 20 percent; Danish pastries prepared according to the authentic formula may have about 30 percent; pie crusts may contain even more. High usage levels require those shortenings that melt above room temperature; butter and liquid shortenings, with their lower melting point, tend to leak from the product.

Commercial shortenings may include antioxidants, to retard rancidity, and emulsifiers, to improve the shortening effect. Colours and flavours simulating butter may also be added. Margarines, emulsions of fat, water, milk solids, and salt, are popular bakery ingredients.

Fats of any kind have a destructive effect on meringues and other protein-based foams; small traces of oil left on the mixing utensils can deflate an angel food cake to unacceptably high density.

Liquids

Water is the liquid most commonly added to doughs. Milk is usually added to commercial preparations in dried form, and any moisture added in the form of eggs and butter is usually minimal. Water is not merely a diluent or inert constituent; it affects every aspect of the finished product, and careful adjustment of the amount of liquid is essential to make the dough or batter adaptable to the processing method. If dough is too wet it will stick to equipment and have poor response to shaping and transfer operations; if too dry, it will not shape or leaven properly.

Water hydrates gluten, permitting it to aggregate in the form of a spongy cellular network, the structural basis of most bakery products. It provides a medium in which yeast can metabolize sugars to form carbon dioxide and flavouring components and allows diffusion of nutrients and metabolites throughout the mass. Water is an indispensable component of the baking-powder reaction, and it allows starch to gelatinize during baking and prevents interior browning of bakery products.

Water impurities affect dough properties. Water preferred for baking is usually of medium hardness (50 to 100 parts per million) with a neutral pH (degree of acidity), or slightly acid (low pH). Water that is too soft can result in sticky doughs, while very hard water may retard dough expansion by toughening the gluten (calcium ions, particularly, promote cross-linking of gluten protein molecules). Water sufficiently alkaline to raise the dough pH may have a deleterious effect on fermentation and on flour enzymes. Although strongly flavoured contaminants may affect the acceptability of the finished product, chlorides and fluorides at concentrations usually found in water supplies have little influence on bread doughs.

Eggs

The differences between yolks and whites must be recognized in considering the effect of eggs on bakery products. Yolks contain about 50 percent solids, of which 60 percent or more is strongly emulsified fat, and are used in bakery foods for their effect on colour, flavour, and texture. Egg whites, containing only about 12 percent solids, primarily protein, and no fat, are important primarily for their texturizing function and give foams of low density and good stability when beaten. When present in substantial amounts, they tend to promote small, uniform cell size and relatively large volume. Meringues and angel food cakes are dependent on egg white foams for their basic structure. Although fats and oils greatly diminish its foaming power, the white still contributes to the structure of layer cakes and similar confections containing substantial amounts of both shortening and egg products.

Egg products are available to bakers in frozen or dried form. Few commercial bakers break fresh eggs for ingredients because of labour costs, unstable market conditions, and sanitary considerations. Many bakers use dried egg products because of their greater convenience and superior storage stability over frozen eggs. Processed and stored correctly, dried egg products are the functional equivalent of the fresh material, although flavour of the baked goods may be affected adversely at very high usage levels.

Sweeteners

Normal wheat flour contains about 1 percent sugars. Most are fermentable compounds, such as sucrose, maltose, glucose, and fructose. Additional maltose is formed during fermentation by the action of amyloytic enzymes (from malt and flour) on the starch. Glucose and sucrose are the sugars most frequently added to doughs and batters. The action of yeast rapidly converts the sucrose to fructose and glucose (i.e., invert sugar). Invert sugar can also be added.

Sweetening power is an important property of added sugars, but sugars also provide fermentables for yeast activity. Crust colour development is related to the amount of reducing sugars present, and a dough in which the sugars have been thoroughly depleted by yeast will produce a pale crust.

Doughs with high concentrations of dissolved substances retard fermentation because of the effect on yeast of the high osmotic pressure (low water activity) of the aqueous phase. Sugars constitute the bulk of dissolved materials in most doughs. For this reason, sweet yeast-leavened goods develop gas and expand more slowly than bread doughs.

Yeast-leavened products

Breads and rolls

Most of the bakery foods consumed throughout the world are breads and rolls made from yeast-leavened doughs. The yeast-fermentation process leads to the development of desirable flavour and texture, and such products are nutritionally superior to products of the equivalent chemically leavened doughs, since yeast cells themselves add a wide assortment of vitamins and good quality protein.

Bread

Baked food product made of flour or meal that is moistened, kneaded, and sometimes fermented. A major food since prehistoric times, it has been made in various forms using a variety of ingredients and methods throughout the world. The first bread was made in Neolithic times, nearly 12,000 years ago, probably of coarsely crushed grain mixed with water, with the resulting dough probably laid on heated stones and baked by covering with hot ashes. The Egyptians apparently discovered that allowing wheat doughs to ferment, thus forming gases, produced a light, expanded loaf, and they also developed baking ovens.

Flat breads, the earliest form of bread, are still eaten, especially in much of the Middle East, Asia, and Africa. The principal grains used in such breads are corn (maize), barley, millet, and buckwheat—all lacking sufficient gluten (elastic protein) to make raised breads—and wheat and rye. Millet cakes and chapaties (crisp, whole-meal cakes) are popular types in India. Corn is used to make the small, flat cakes known as tortillas, important throughout much of Latin America; and in Brazil small cakes are made from cassava.

Although Far Eastern peoples have traditionally preferred rice, consumed as a grain, consumption of Western breads was increasing there in the latter half of the 20th century; and in Japan the bread-baking industry, using U.S. processes, expanded rapidly after World War II. Raised black bread, common in Germany, Russia, and Scandinavia, is made chiefly from rye. Lighter rye loaves, with wheat flour added, are popular in the United States. Raised wheat breads include white bread, made from finely sifted wheat flour; whole wheat bread, made from unsifted flour containing much of the outer and inner portions of the wheat kernel normally removed for white flour; gluten bread, lower in sugars because much of the starch is removed from the flour; and Vienna and French bread, long, narrow, crusty loaves. Other forms of raised breads include rolls and buns, chemically leavened quick breads, and yeast-leavened sweet goods that are rich in sugar and shortening.

Although raised bread originally relied upon spontaneous fermentation, bakers learned to produce fermentation with yeast. Specific strains have been developed with useful bread-making qualities, including stability, rapid fermentation capacity, and the ability to withstand high temperatures, all permitting production of a uniform product. Only wheat and rye flours produce the necessary gluten to make raised loaves, and wheat gluten is more satisfactory for this purpose. Other ingredients include liquids, such as milk or water, shortenings of animal or vegetable origin, salt, and sugar.

Improvements in the commercial production of bread include better temperature control, handling methods, fuels, and refrigeration.

Modern commercial bread making is highly mechanized. Mixing is performed by the straight-dough or sponge-dough methods or the newer continuous-mixing process. In the straight-dough method, frequently used in small bakeries, all ingredients are mixed at one time. In the sponge-dough method, only some of the ingredients are mixed, forming a sponge that is allowed to ferment and is then mixed with the remaining ingredients to form the dough. The mixed dough is divided into appropriately sized pieces, deposited in bakery pans, and allowed to rise. The pans then pass through a travelling tray oven, baking the bread. The continuous-mixing process eliminates many individual operations.

Etymology

The word itself, Old English bread, is common in various forms to many Germanic languages; such as German Brot, Dutch brood, Swedish bröd, and Norwegian brød; it has been derived from the root of brew, but more probably is connected with the root of break, for its early uses are confined to broken pieces, or bits of bread, the Latin frustum, and it was not until the 12th century that it took the place—as the generic name for bread—of hlaf (modern English loaf), which appears to be the oldest Teutonic name; Old High German hleib and modern German Laib, or Finnish leipä, Estonian leib, and Russian хлеб (khleb) are similar (all are derived from Old Germanic)

White bread

Satisfactory white bread can be made from flour, water, salt, and yeast. (A “sourdough” addition may be substituted for commercial yeast.) Yeast-raised breads based on this simple mixture include Italian-style bread and French or Vienna breads. Such breads have a hard crust, are relatively light in colour, with a coarse and tough crumb, and flavour that is excellent in the fresh bread but deteriorates in a few hours. In the United States, commercially produced breads of this type are often modified by the addition of dough improvers, yeast foods, mold inhibitors, vitamins, minerals, and small quantities of enriching materials such as milk solids or shortening. Formulas may vary greatly from one bakery to another and between different sections of the country. The standard low-density, soft-crust bread and rolls constituting the major proportion of breads and rolls sold in the United States contain greater quantities of enriching ingredients than the lean breads described above.

Whole wheat bread

Whole wheat bread, using a meal made substantially from the entire wheat kernel instead of flour, is a dense, rather tough, dark product. Breads sold as wheat or part-whole-wheat products contain a mixture of whole grain meal with sufficient white flour to produce satisfactory dough expansion.

Rye bread

Bread made from crushed or ground whole rye kernels, without any wheat flour, such as pumpernickel, is dark, tough, and coarse-textured. Rye flour with the bran removed, when mixed with wheat flour, allows production of a bread with better texture and colour. In darker bread it is customary to add caramel colour to the dough. Most rye bread is flavoured with caraway seeds.

Potato bread

Potato bread, another variety that can be leavened with a primary ferment, was formerly made with a sourdough utilizing the action of wild yeasts on a potato mash and producing the typical potato-bread flavour. It is now commonly prepared from a white bread formula to which potato flour is added.

Sweet breads

Ingredients

Sweet goods made from mixtures similar to bread doughs include “raised” doughnuts, Danish pastries, and coffee cakes. Richer in shortening, milk, and sugar than bread doughs, sweet doughs often contain whole eggs, egg yolks, egg whites, or corresponding dried products. The enriching ingredients alter the taste, produce flakier texture, and improve nutritional quality. Spices such as nutmeg, mace, cinnamon, coriander, and ginger are frequently used for sweet-dough products; other common adjuncts include vanilla, nuts and nut pastes, peels or oils of lemon or orange, raisins, candied fruit pieces, jams, and jellies.

Danish dough

Although various portion-size sweet goods are often called “Danish pastry,” the name originally referred only to products made by a special roll-in procedure, in which yeast-leavened dough sheets are interleaved with layers of butter and the layers are reduced in thickness, then folded and resheeted to obtain many thin layers of alternating shortening and dough. Danish doughs ordinarily receive little fermentation. Before the fat is rolled in, there is a period of 20 to 30 minutes in the refrigerator, allowing gas and flavour to develop. Proof time, fermentation of the piece in its final shape, is usually only 20 to 30 minutes, at lower temperatures. When properly made, these doughs yield flaky baked products, rich in shortening, with glossy crusts.

Wafers and biscuits

Rye wafers made of whipped batters are modern versions of an ancient Scandinavian food. High-moisture dough or batter, containing a substantial amount of rye flour and some wheat flour, is whipped, extruded onto an oven belt, scored and docked, then baked slowly until almost dry. Alternatively, the strips of dough may be cut after they are baked.

Beaten biscuits, an old specialty of the American South, are also made from whipped batter. Air is beaten into a stiff folded dough with many strokes of a rolling pin or similar utensil. Round pieces cut from the dough are pricked with a fork to prevent development of large bubbles, then baked slowly. The baked biscuit is similar to a soft cracker.

Puff pastry

Puff pastry, often used in French pastries, is formed from layered fat and dough. The proportion of fat is usually high, rarely less than 30 percent of the finished raw piece. The dough should be extensible but not particularly elastic; for this reason mixtures of hard and soft wheat flour are often used. The fat should have an almost waxy texture and must remain solid through the sheeting steps. Butter, although frequently used, is not particularly suitable for puff pastry because its low melting point causes it to blend into the dough during the sheeting process. Bakers specializing in puff pastry often use special margarines containing high-melting-point fats.

There are several methods of making puff pastry. In the basic procedure dough is rolled into a rectangular layer of uniform thickness, and the fat is spread over two-thirds of the surface. The dough is next folded, producing three dough strata enclosing two fat layers. This preparation is next chilled by refrigeration, then rolled, reducing thickness until it reaches approximately the area of the original unfolded dough. The folding, refrigeration, and rolling procedure is repeated several times, and after the final rolling the dough is reduced to the thickness desired in the shaped raw piece.

Correctly prepared puff pastry will expand as much as 10 times during baking because of the evolution of large volumes of steam at the interface between shortening and dough. The focuses for gassing are the microscopic air bubbles rolled into the dough during the layering process. If layering has been properly conducted, the finished pieces will be symmetrical and well-shaped, with crisp, flaky outer layers.

Chou paste

Choupaste, used for cream puffs, is made by an entirely different method. Flour, salt, butter, and boiling water are mixed together, forming a fairly stiff dough, and whole eggs are incorporated by beating. Small pieces of the dough are baked on sheets, initially at high temperature. The air bubbles formed during mixing expand rapidly at baking temperatures, filling the interior with large, irregular cells, while the outside browns and congeals, forming a rather firm case. The interior, largely hollow, can be injected with such sweet or savoury fillings as whipped cream or shrimp in sauce.

Unleavened products: pie crusts

Pie crusts are the major volume item of unleavened products prepared by modern bakeries. Small amounts of baking powder or soda are sometimes added to pie-crust doughs, mostly in domestic cookery. This addition, although increasing tenderness, tends to eliminate the desirable flakiness and permits the filling liquid to soak into the crust more rapidly.

Pie crusts are usually simple mixtures of flour, water, shortening, and salt. The shortening proportion is about 30 to 40 percent of the dough. The amount of water is kept low, and the mixing process is kept short to minimize development of elasticity, which leads to shrinkage and development of toughness on baking. For flaky crust the fat should not be completely dispersed through the dough but should remain in small particles. Commercial producers often employ special mixers using reciprocating, intermeshing arms to gently knead the dough. The doughs are chilled before mixing and forming to reduce smearing of the shortening.

Flakiness is also related to the type of shortening used. Lard is popular in home cookery for this reason and also because of its satisfying flavour. Because shortening should be solid at the temperature of mixing, oils are undesirable.

Milk or small amounts of corn sugar may be added to improve crust browning and for their flavour effect. About 1 to 2 percent of the dough will be salt.

Flat breads

A large part of the world's population consumes so-called flat breads on a daily basis. Tortillas and pita bread are representative examples. Traditional tortillas are made from a paste of ground corn kernels that have been soaked in hot lime water. Corn tortillas contain no leaveners, although a wheat-flour version, which is gradually replacing the corn product, frequently contains a small amount of baking powder. Pita bread is a very thin disk of yeast-leavened dough that has been prepared so as to cause separation of the top and bottom surfaces of the baked product except at the circumference.

The dough portion of pizzas also can be considered a type of flat bread. Other examples can be found that vary widely in size, shape, and composition, although nearly all of them are based on a lean, yeast-leavened dough of rather tough consistency.

Extracted from "Baking." Encyclopædia Britannica from Encyclopædia Britannica 2007 Ultimate Reference Suite. (2011) and http://en.citizendium.org/wiki/bread. Digitized, adapted and illustrated to be posted by Leopoldo Costa.

No comments:

Post a Comment

Thanks for your comments...